MUTOH Clear Tone

Original half tone technology

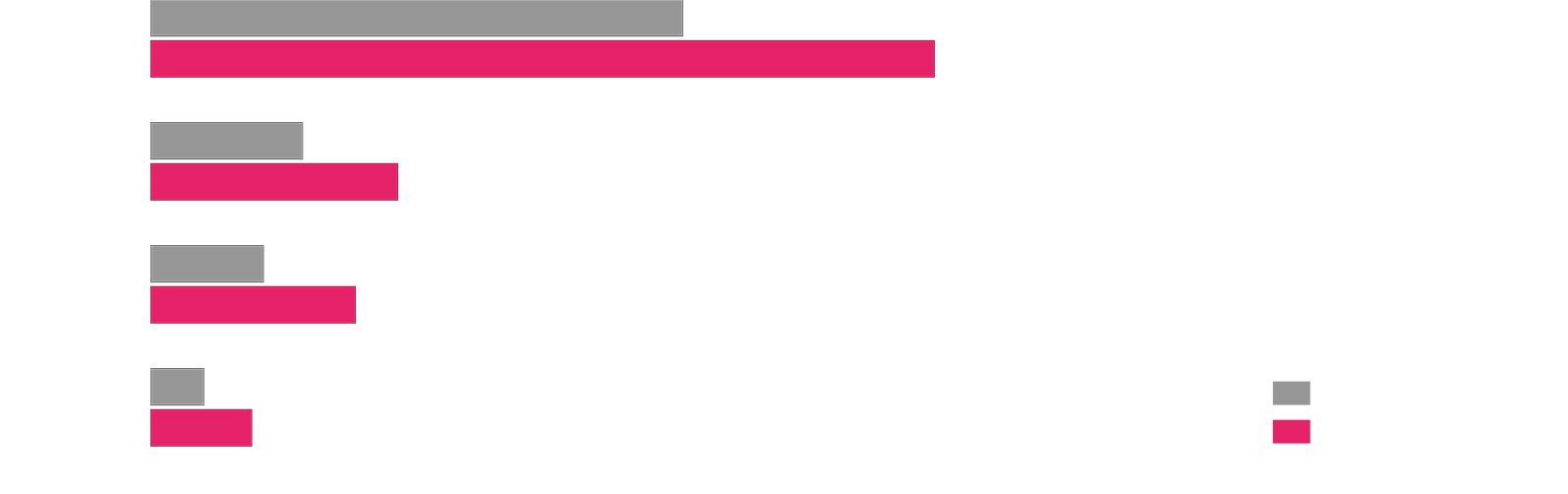

Less variation in color density and smoother gradations

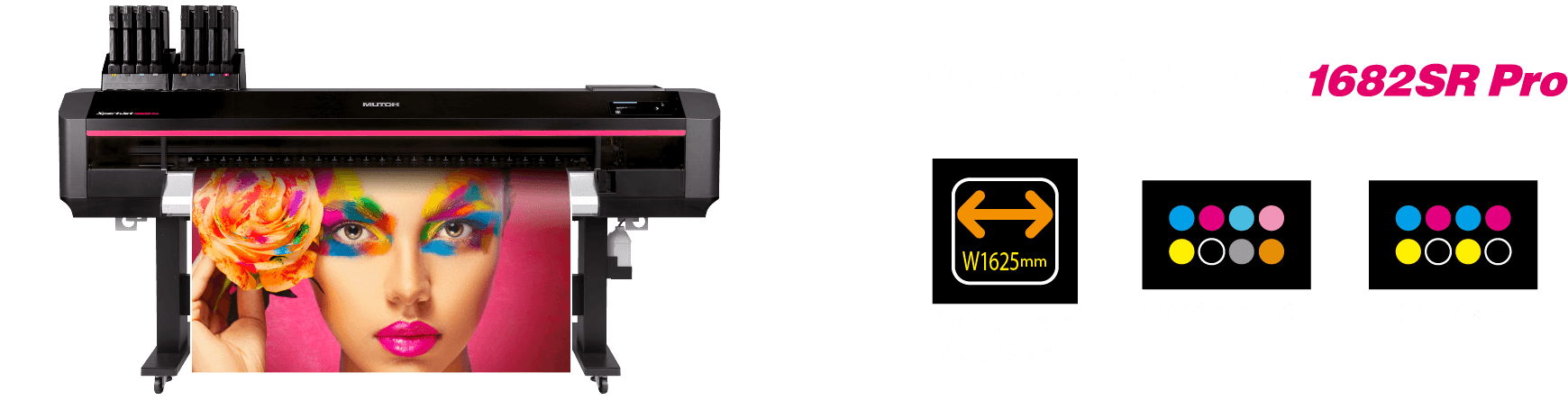

The XpertJet 1682SR Pro is equipped with two units of AccuFine HD with more nozzles, which is newly added to extra wide and high-density piezo print head, AccuFine. Compared to the conventional model, the XpertJet 1682SR Pro is up to 189 %* faster. In addition, this model inherits a platform designed to improve operability and reduce operator workload, it is equipped with various functions to provide high user assistance. The Xpertet 1682SR Pro is the flagship model of the XpertJet series that deliver "high image quality" and "high productivity" by combining MUTOH's unique traditional and advanced technologies. *Comparison between the new High Quality mode and the conventional Quality2 mode (8-color configuration)

The MS41 eco-solvent ink paired with the printer excels in color development, weather resistance, and ease of maintenance. The ink has been certified UL GREENGUARD Gold, making it environmentally and also operator friendlier.

The XpertJet 1682SR Pro brings the best "Made in Japan Quality" to various markets such as banners, trade show graphics, indoor and outdoor signs, POP displays, vehicle wrap and more.

Up to 179% productivity compared to conventional model

Up to 189% productivity compared to conventional model

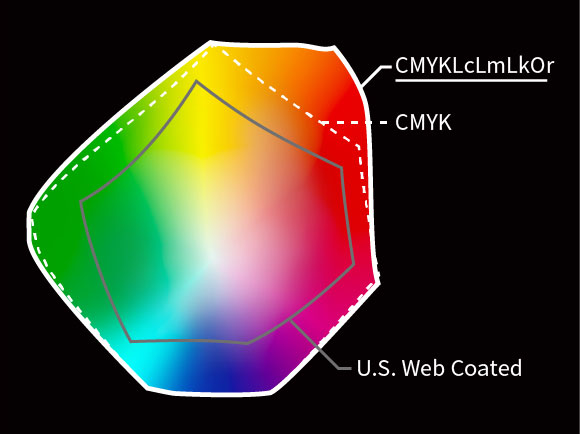

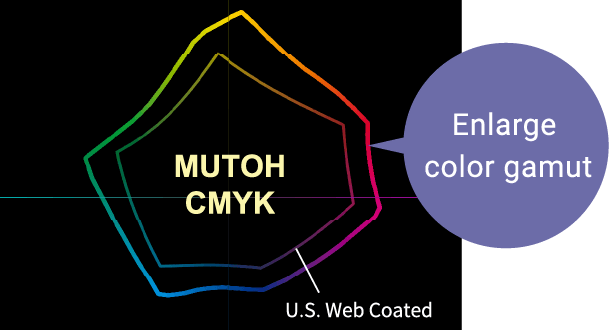

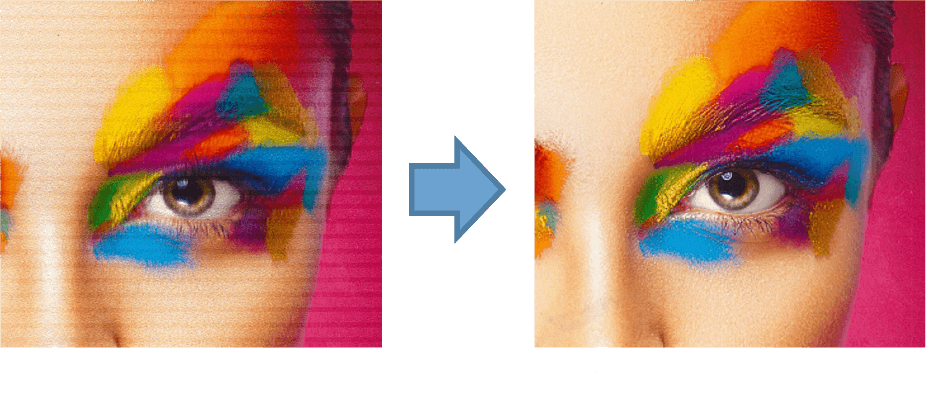

In 8 color-configuration, the “natural and smooth gradation” of the light inks and the "rich expression" and "vivid color development“ of the warm colors enhanced by the orange ink delivers printing with "beauty" and "impact" that is ideal for Sign & Graphics.

Orange ink expands the color gamut

for rich expression

Clearer and more vivid colors

*Images are for illustrative purposes only. They may differ from actual printed materials.

UL

GREENGUARD Gold

Certification

High-precision printing

that MUTOH’s traditional unique technology "high-precision aluminum rail structure" achieves

High quality printing

that MUTOH’s latest unique technologies “AccuFine”,

“i-screen” and “VerteLith” achieve

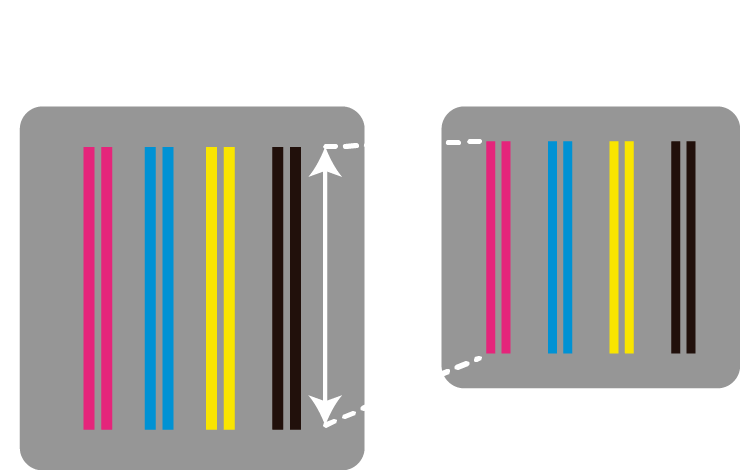

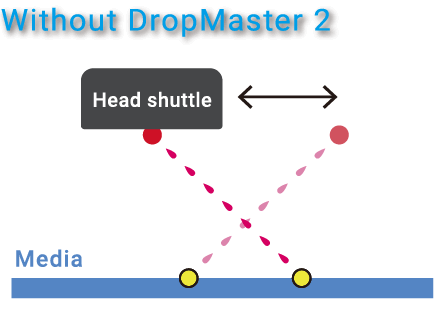

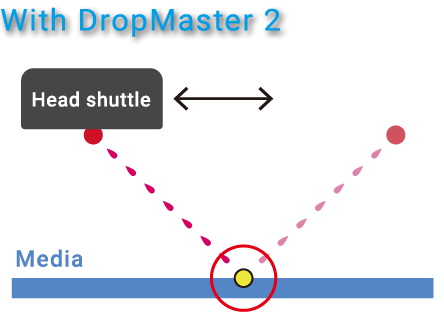

“AccuFine" is a new extra wide and high density piezo print head, and achieves both high image quality and high-speed printing by dramatically improving the landing accuracy. High quality solid printing with less banding even at high speed

Increased nozzle row length

Contributes to higher productivity

*This is different from the actual ink arrangement.

High density nozzle pitch

Contributes to higher image quality

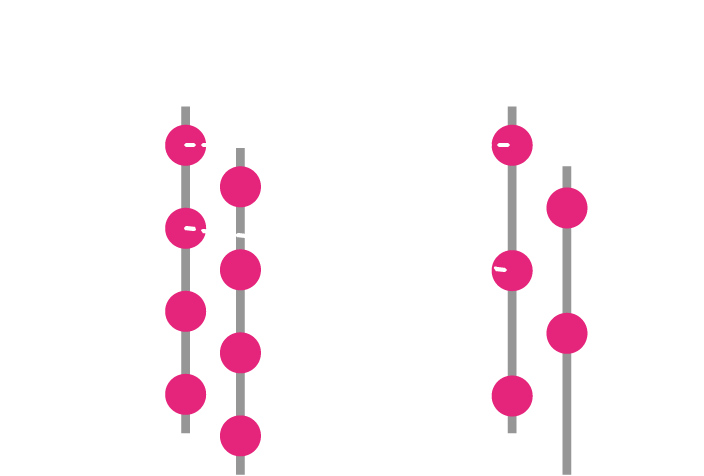

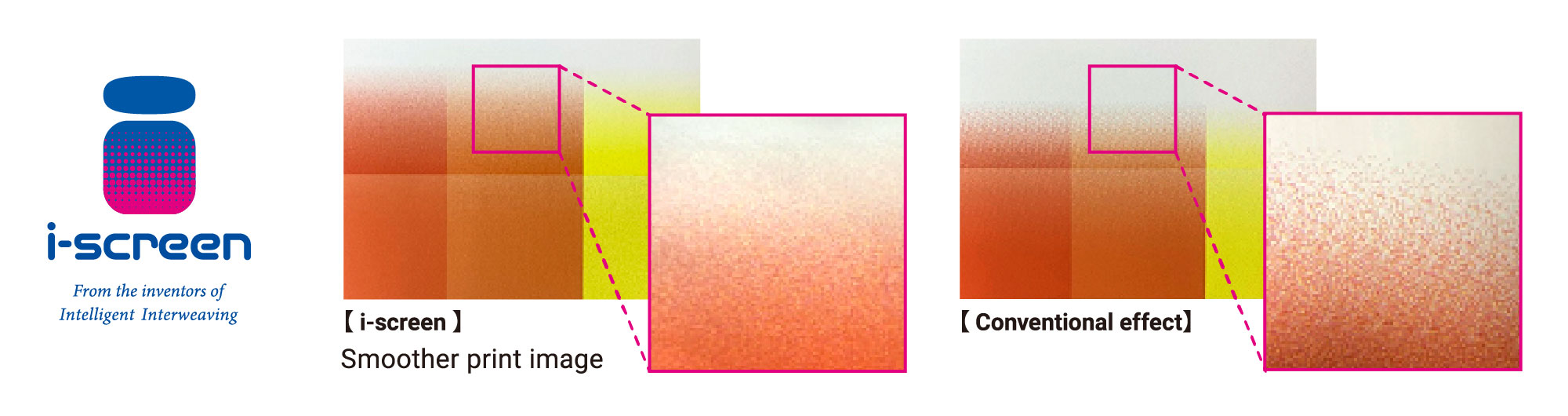

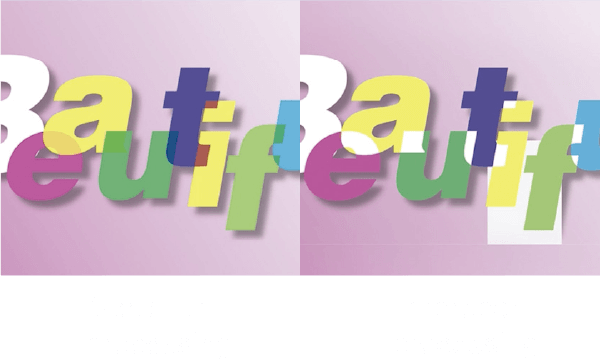

“i-screen” was created by optimizing the “AcuuFine“ and evolving MUTOH’s ”Intelligent Interweave” printing technology.

By arranging the dots in a way that takes into account how they look, this reduces banding for smoother print images.

Less variation in color density and smoother gradations

ICC input profile “MUTOH CMYK” maximizes the coverage of color gamut

More reliable output by accurate processing of PDF transparencies & drop shadows

Built-in sensor on the carriage automatically calibrates bi-directional alignments, and saves time and reduces validation in adjustment among different operators.

By printing a print pattern and reading it with a sensor, paper feed correction can be automated. This reduces the time and effort required for adjustment and media loss.

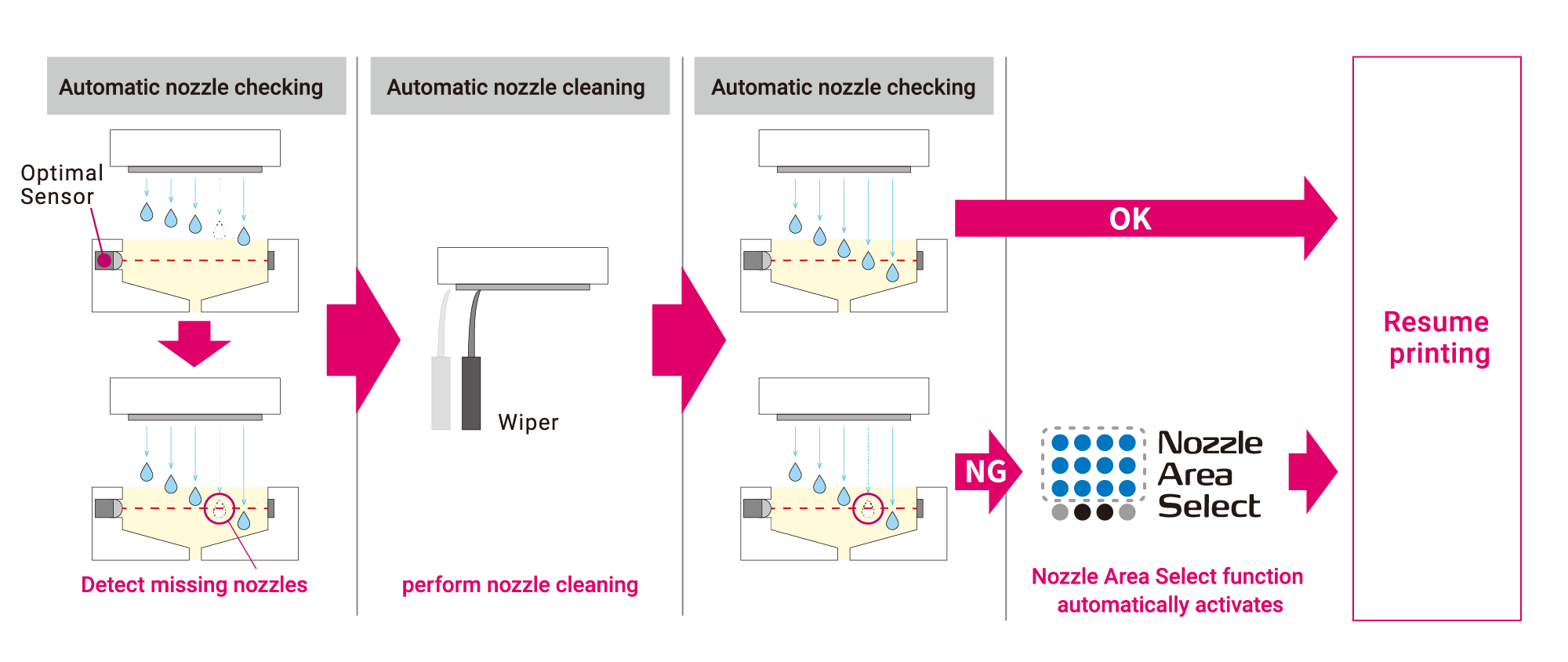

Nozzle area select temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover. This is a reliable function that ensures seamless operation.

Media tracker manages the remaining media by printing barcodes before removing a roll in use. It will read the barcode when reloading that roll. Streamlines management of remaining capacity for multiple media.

It is available to add a module to the print head that can optically monitor the ink jetting. Automatically detects missing nozzles and performs nozzle cleaning. If nozzles are not recovered, the Nozzle Area Select automatically activates to continue printing.

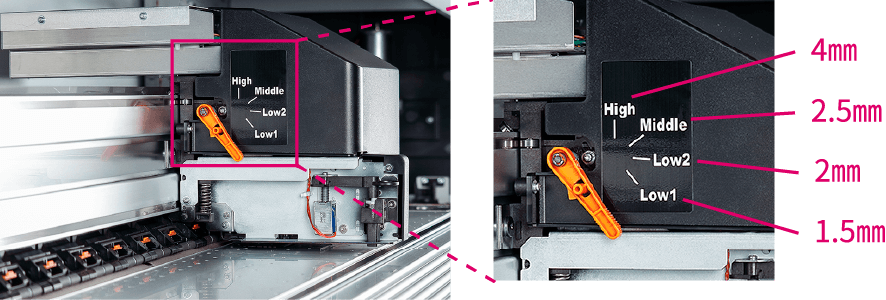

PG setting enhanced with 4 steps allows the operators to select the optimal print head height for the media being used. It reduces the risk of print head contact and maintain stable print quality.

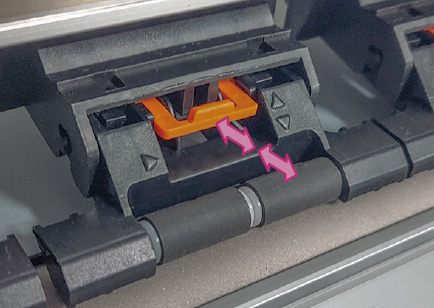

Media feeding power is affected by pressure and paper thickness. This pressure mode can be set to four levels: high, middle, low and partial pressure by adjusting the position of the media set lever and the pressure arms, which expands media feed capability. Thin paper and soft media could not be fed by conventional solvent machines now can be supported by setting the pressure low. Furthermore, media cockling can be minimized by canceling multiple pressure rollers individually.

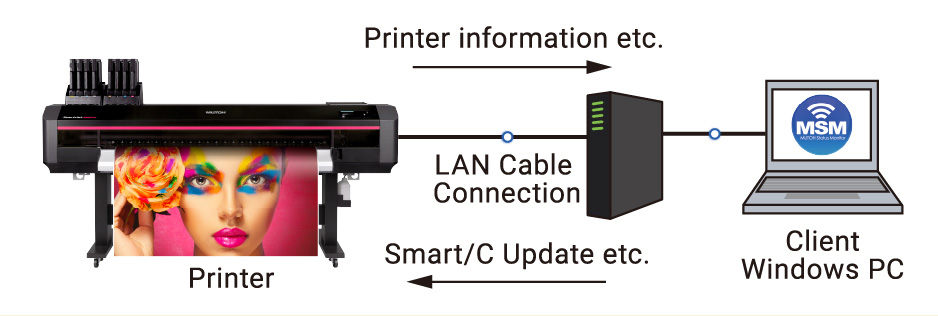

MUTOH Status Monitor is software that enables the checking of the printer operation status from a computer in real time.

The following information can be confirmed for your MUTOH printer.

Print history can be exported as a CSV file.

Discover XpertJet 1682SR Pro