A 54-inch compact model designed for

high image quality and user convenience

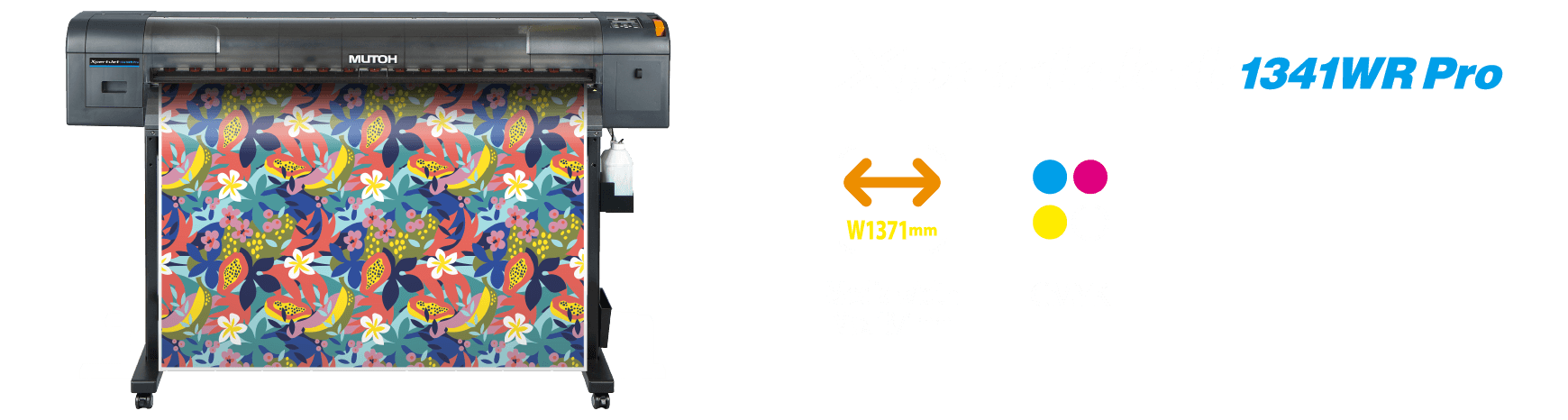

The MUTOH XpertJet series, which delivers excellent print quality and high productivity, now has a 54“/1.3m wide water-based inkjet printer. In a compact body with a space-saving design that's easy to handle, equipped with MUTOH's latest unique technologies, the XpertJet 1341WR Pro is designed for high image quality and user convenience.

The MUTOH original dye-sublimation ink provides superior media transfer, achieves high density colors with less ink consumption. The fast ink drying enables printings on thinner/lighter transfer papers, and excellent jetting performance and color stability provide high-quality output.

The XpertJet 1341WR Pro is an ideal printer for trade show graphics, flags, banners, custom interior design, apparel, custom merchandise and more.

Print technologies for high productivity and high image quality

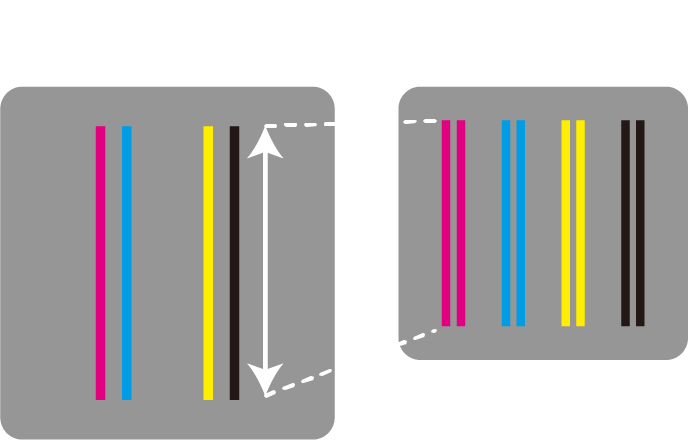

"AccuFine" extra wide and high density piezo print head, delivering the best in class ink drop placement accuracy, achieves both high-speed printing and high image quality. Even at high speed, the “AccuFine” can produce high-quality solid printing with less banding.

Increased nozzle row length

Contribute to higher productivity

*This is different from the actual ink arrangement.

High density nozzle pitch

Contribute to higher image quality

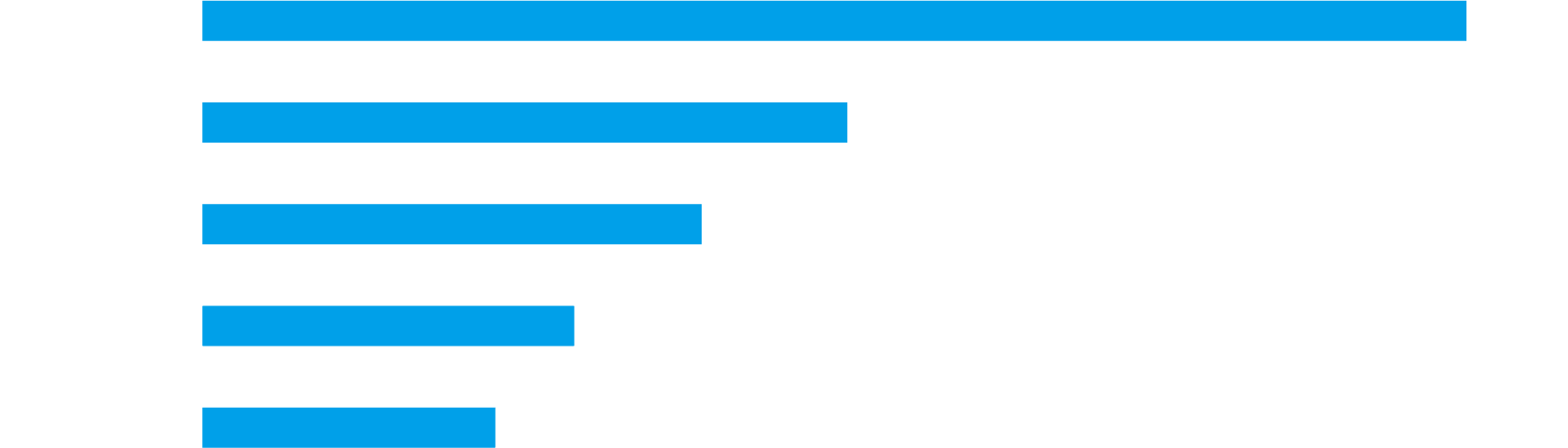

◆Throughput of XpertJet 1341WR Pro (m2/h)

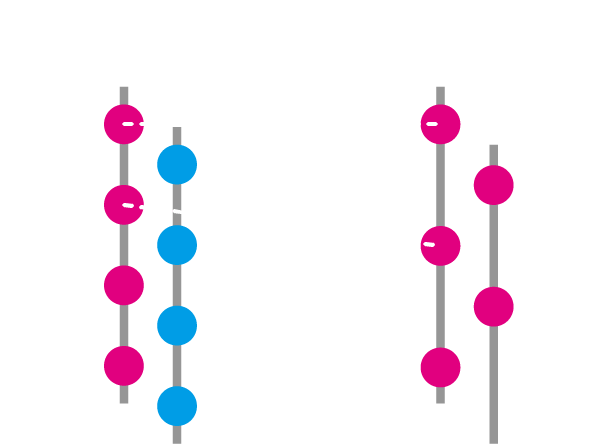

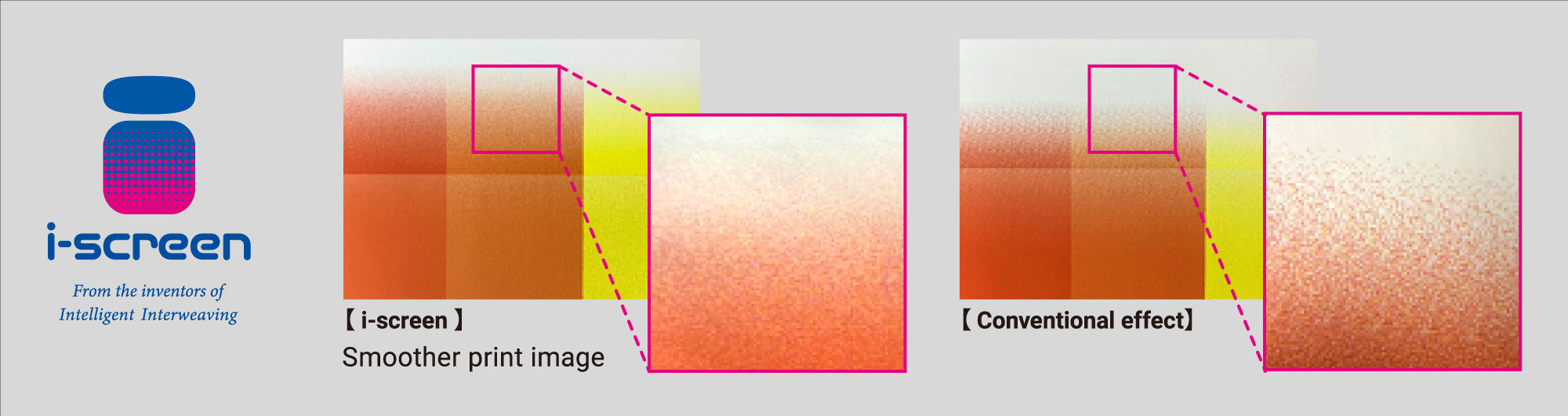

New print effect “i-screen” on board

“i-screen” was created by optimizing the AccuFine and evolving MUTOH’s ”Intelligent Interweave” printing technology.

By arranging the dots in a way that takes into account how they look, this reduces banding for smoother print images.

MUTOH's unique technologies for automation and efficiency

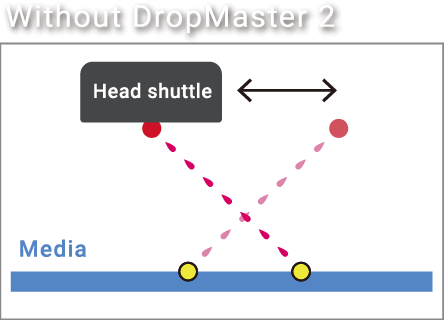

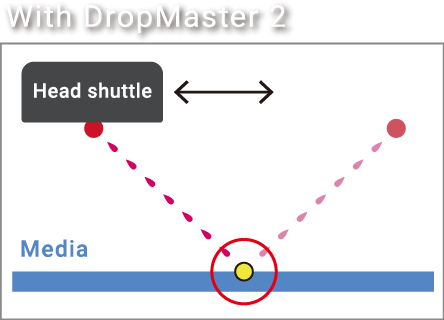

Automatic Bi-D adjustment

“DropMaster 2”

Built-in sensor on the carriage

automatically calibrates bi-directional alignments, and saves time and reduces validation in adjustment among different operators.

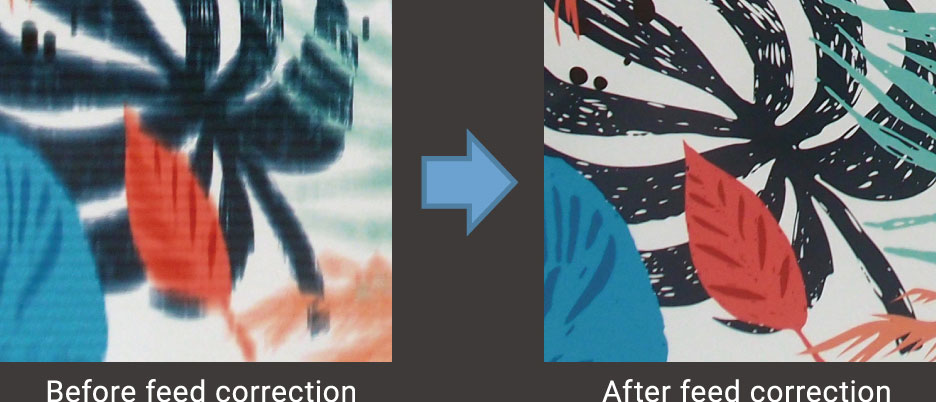

Automatic media feed adjustment

“Feed Master”

By printing a print pattern and reading it with a sensor, paper feed correction can be automated. This reduces the time and effort required for adjustment and media loss.

Nozzle selection Function

"Nozzle Area Select"

Nozzle area select temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover. This is a reliable function that ensures seamless operations.

Media roll balance management

“Media Tracker”

Media tracker manages the remaining media by printing barcodes before removing roll in use.It will read the barcode when reloading that roll. Streamlines management of remaining capacity for multiple media.

High media compatibility

Three head height settings

The optimal print head height can be selected from 3 stages depending on the media being used. This reduces the risk of contact, and also provides stable print quality.

Partial pressure cancel mechanism

To prevent cockling, the pressure rollers can be individually canceled to finely adjust the pressure applied to the media. A wide range of media types can be fed under optimal conditions.

Media feeding and take-up units (optional)

The motorized feeding and take-up devices are indispensable for large-volume output and long output. The MUTOH tension bar system is used in combination with a take-up unit and a media holder for feed, to ensure constant tension and stable image quality.

Edge holder (optional)

The edge holder, which prevents media from floating and shifting, achieves stable media transport. The magnetic system allows for easy installation and removal.

Easy maintenance

Easy daily maintenance and work efficiency

A maintenance door is provided on the standby side of the print head, which makes it easy to remove paper chips and dust from the print head.

The cleaning wiper can be replaced by the customer as needed to reduce downtime.

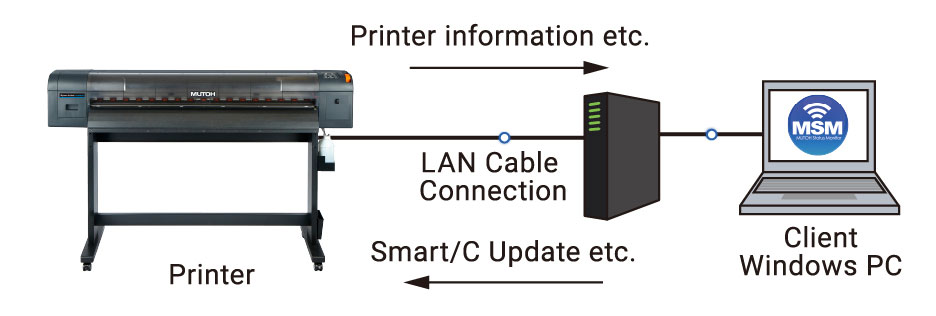

MUTOH Status Monitor (MSM)

A light-weight software enabling remote control of the printer from a computer

In the Status Monitor, the following information can be checked for the MUTOH printer.

- Detailed information

- Status information

- Heater information

- Head temperature/cartridge information

- S/C card information

- Paper information

- Print information

- Print history, etc.

- Multi-language support for all functions (10 languages)

- Print history can be exported as a CSV file.

MUTOH dye sublimation ink DH21

- Excellent transfer performance achieves high color density with low ink volume.

- Fast-drying performance enables printing on thin and light weight transfer paper.

- Superior color rendering performance

- Excellent jetting and color stability support prolong printing.