High productivity and

High image quality

Ability to print on various media

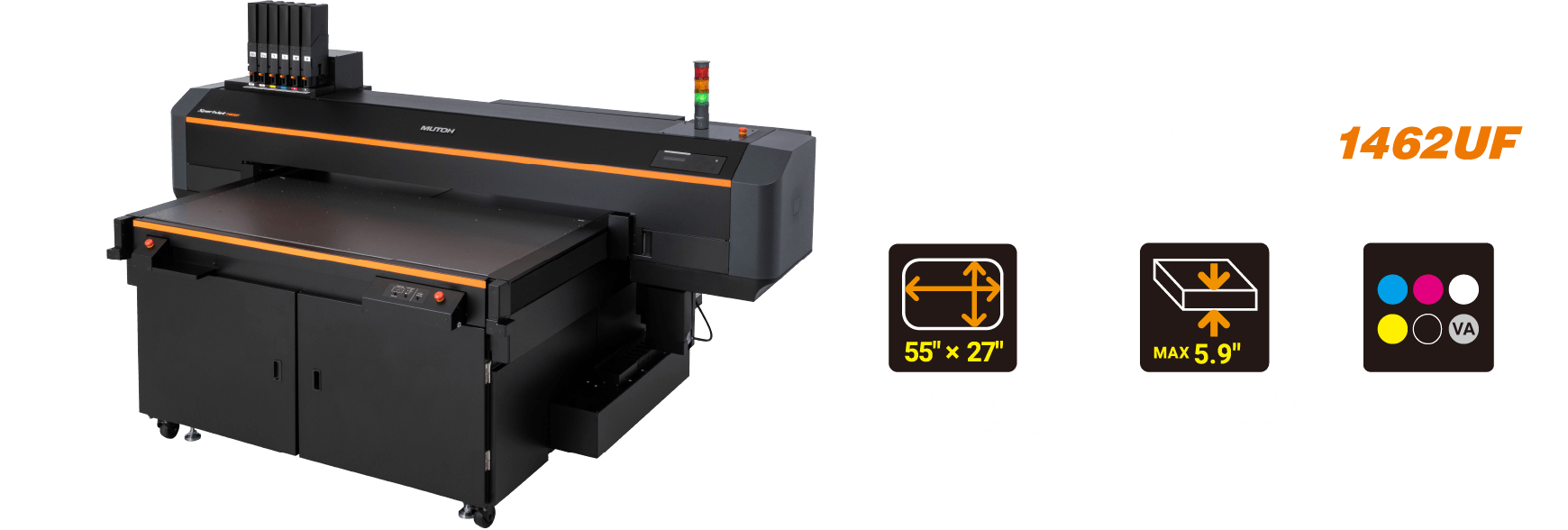

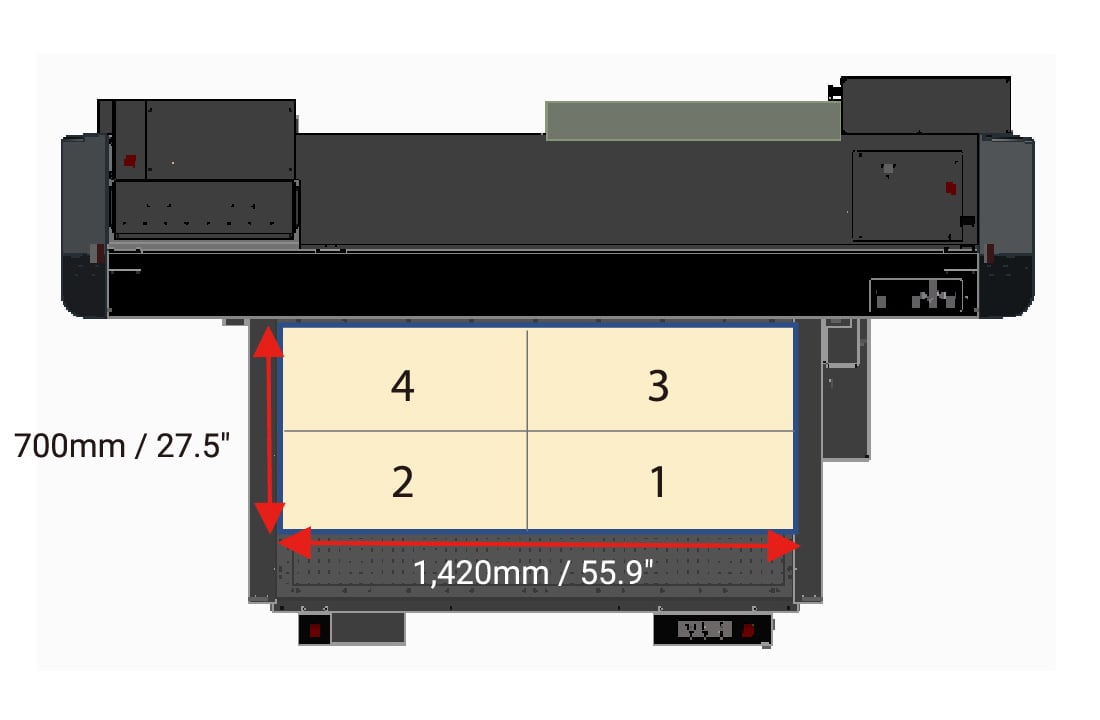

The XpertJet 1462UF is a high-performance flatbed UV-LED printer with moving gantry. The table unit, which supports media up to 1,420 mm (57.9") × 700 mm (27.5"), a thickness of 150 mm (5.9"), and a weight of 50 kg/m², meets diverse user needs with unparalled media adaptability.

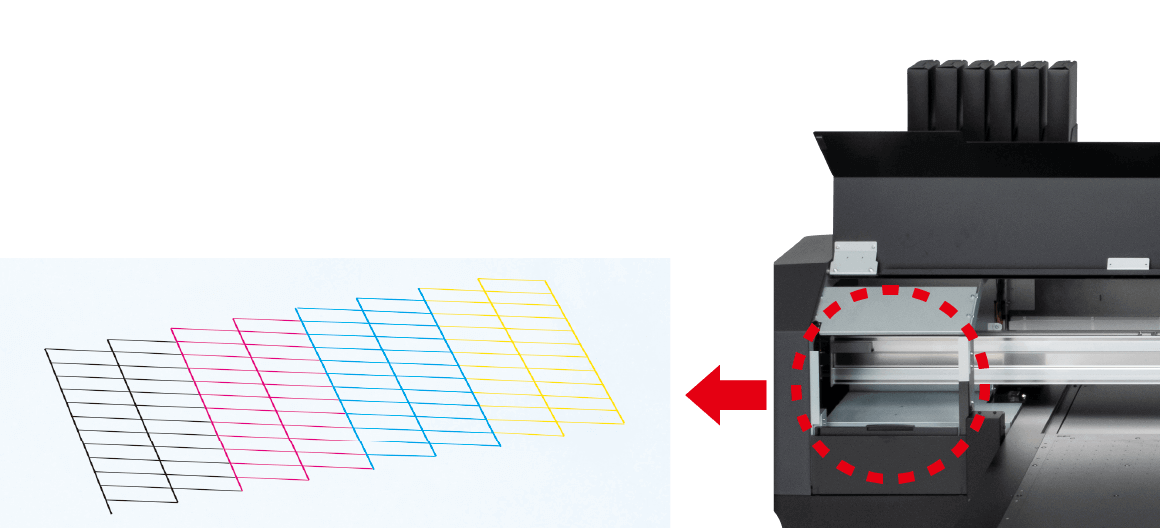

Equipped with two new developed 4-inch UV-LED lamps, the staggered dual print heads with independent CMYK and white/varnish enable 2-layer printing without speed loss. The highly rigid and precise chassis and MUTOH's unique aluminum rail mechanism enable stable and high quality printing with high ink dot placment accuracy.

In addition to the conventional "UH21" ink, a new UV ink "US61" is available for the XpertJet 1462UF. It is a next-generation UV ink which is SVHC (substance of very high concern)-free, offers excellent functionality and compatibility with a wide range of materials while taking into consideration the health of operators and the environment.

The XpertJet 1462UF brings the best "Made in Japan Quality" to various markets such as personalized items, store decoration, sign, industrial products and more.

High quality and high image quality

Two new 4" wide

UV-LED lamps

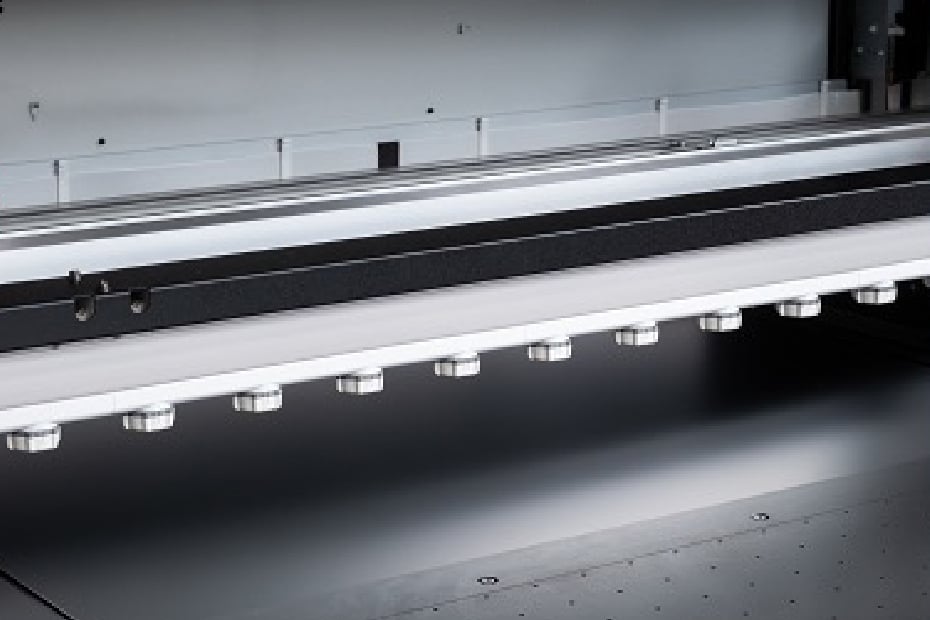

Newly developed 4-inch wide UV-LED lamps are placed on both sides of the print head to achieve high productivity through bi-directional printing. The UV-LED local dimming control technology enables optimal curing for each printing condition.

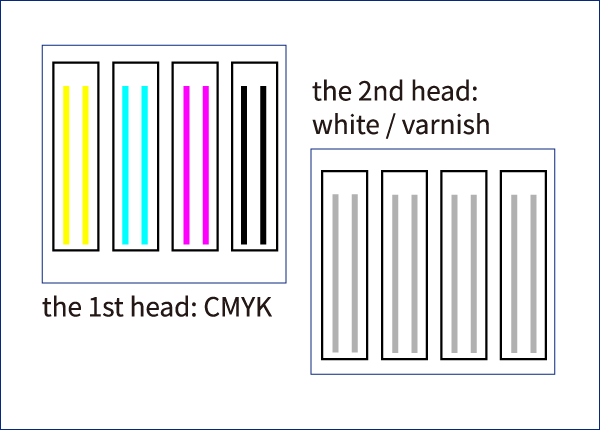

Dual print heads

in a staggered setup

The first head prints CMYK, the second head prints white & varnish which enable 2-layer printing without speed loss. It is also ideal for braille and 2.5D structure prints.

Highly rigid &

high-precise chassis

Highly rigid and precise chassis and MUTOH’s high precision aluminum rail mechanism deliver high ink dot placement accuracy. It enables stable and high-quality printing.

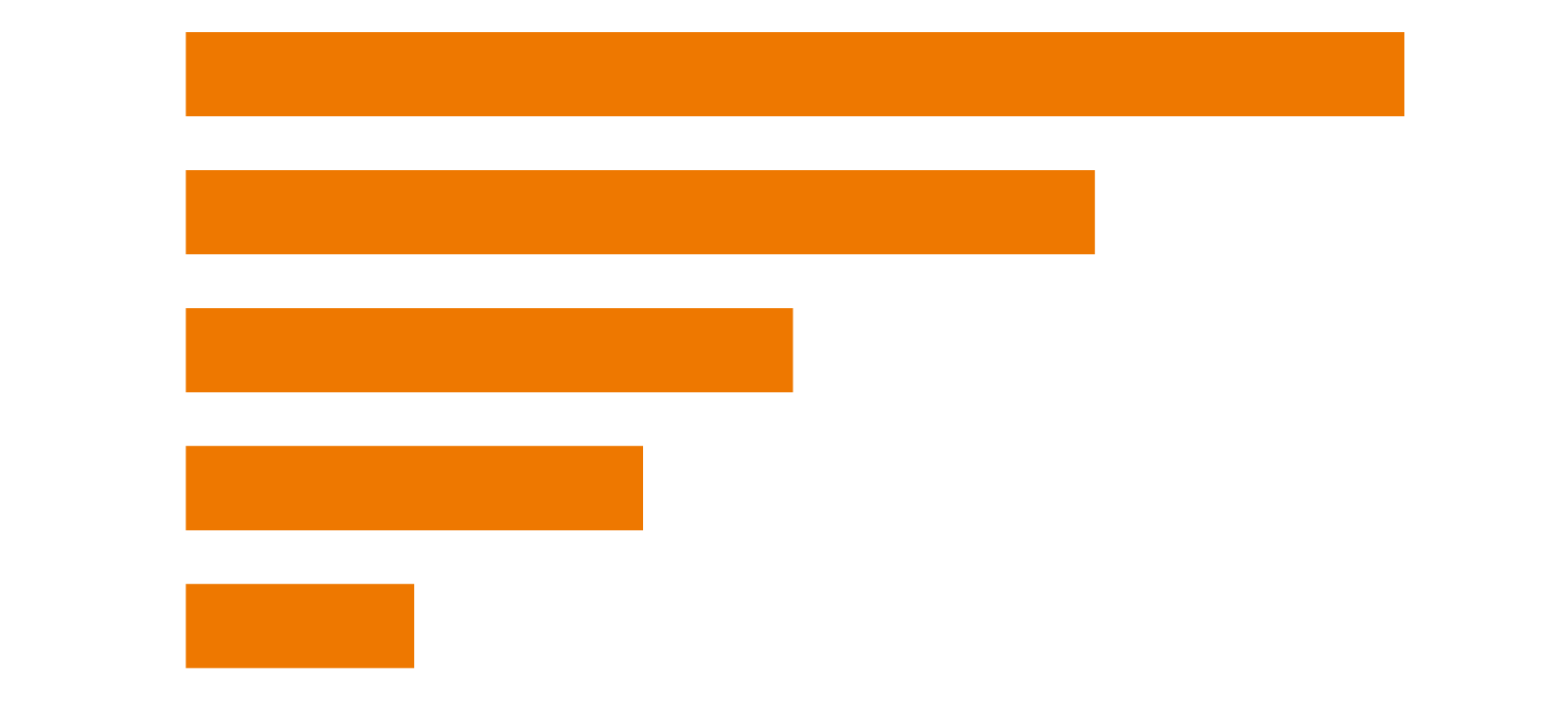

High productivity with a maximum printing speed of 7.75m²/h

Print mode

Printing speed is the same for single layer printing (color or white/varnish only) and 2-layer printing (4C+white or varnish).

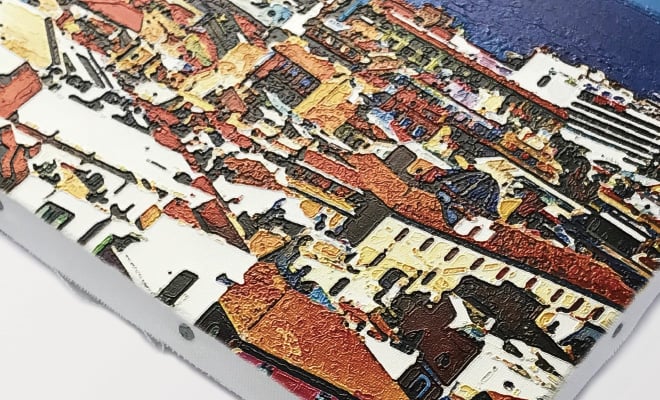

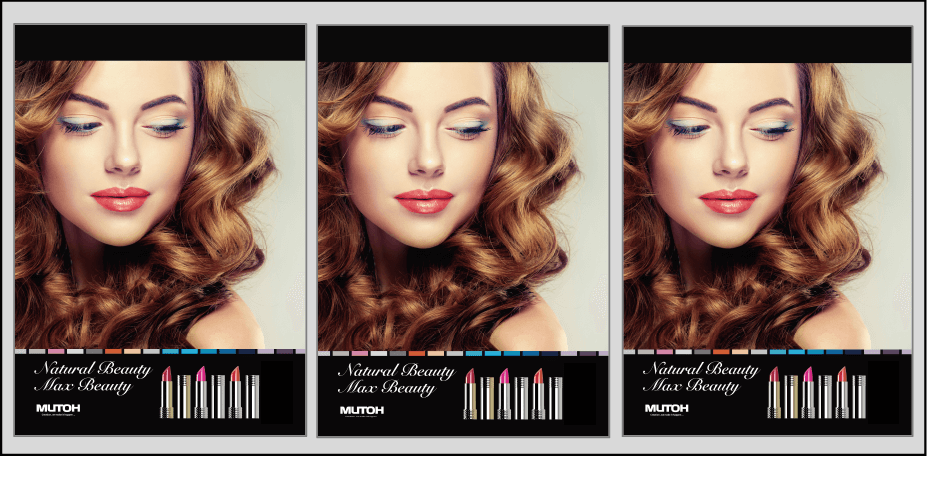

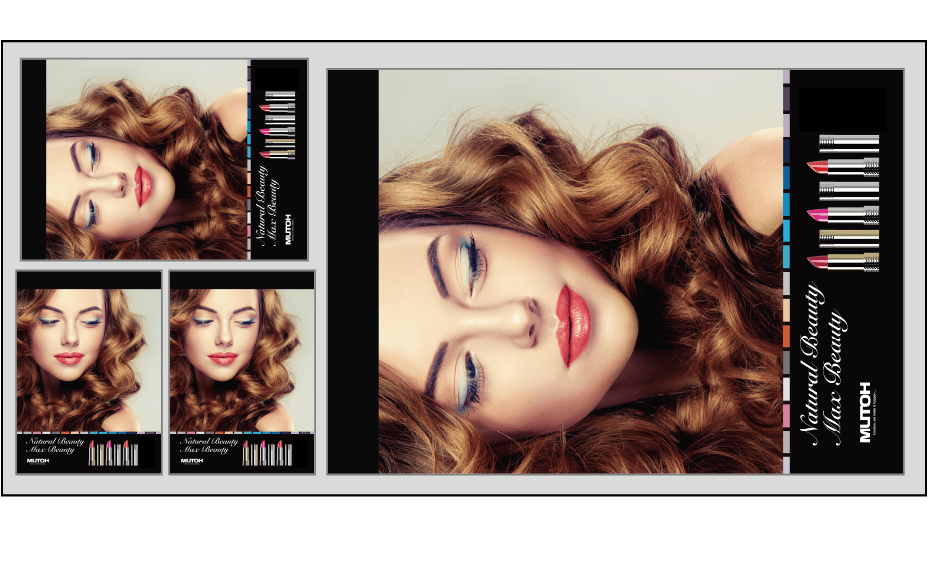

Application samples

*Printed on Versamet Digital Print Metal from Rowmark

Ability to print on various media

4 zone vacuum table

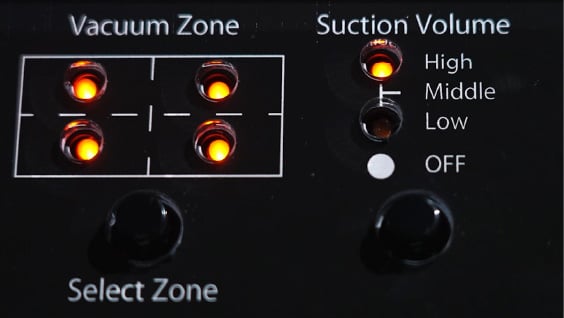

The XPJ-1462UF supports media size of 1,420mm x 700mm (55.9" x 27.5") and can be used for a wide range of applications from large signage to small item printing. It can also be used with materials up to 150mm (5.9") thick and with heavy media and jigs to improve work efficiency. The 4 zone vacuum table, which can be configured for single or multiple area vacuum suction, securely holds a wide variety of media sizes. The suction force can be selected from four levels (high, medium, low, and off).

on the front of the table

vacuum on and off

The vacuum table with marking line for positioning and holes for jig mounting, can be used with magnets, and flexibly support to fix media in various ways. The vacuum holes can also be used as screw holes for fixing jigs.

Media placement example

Ease-of-use features

The simple nozzle check function

Even after the jig and media to be printed are set on the table, nozzle check can be performed at any time in a dedicated area next to the print table.

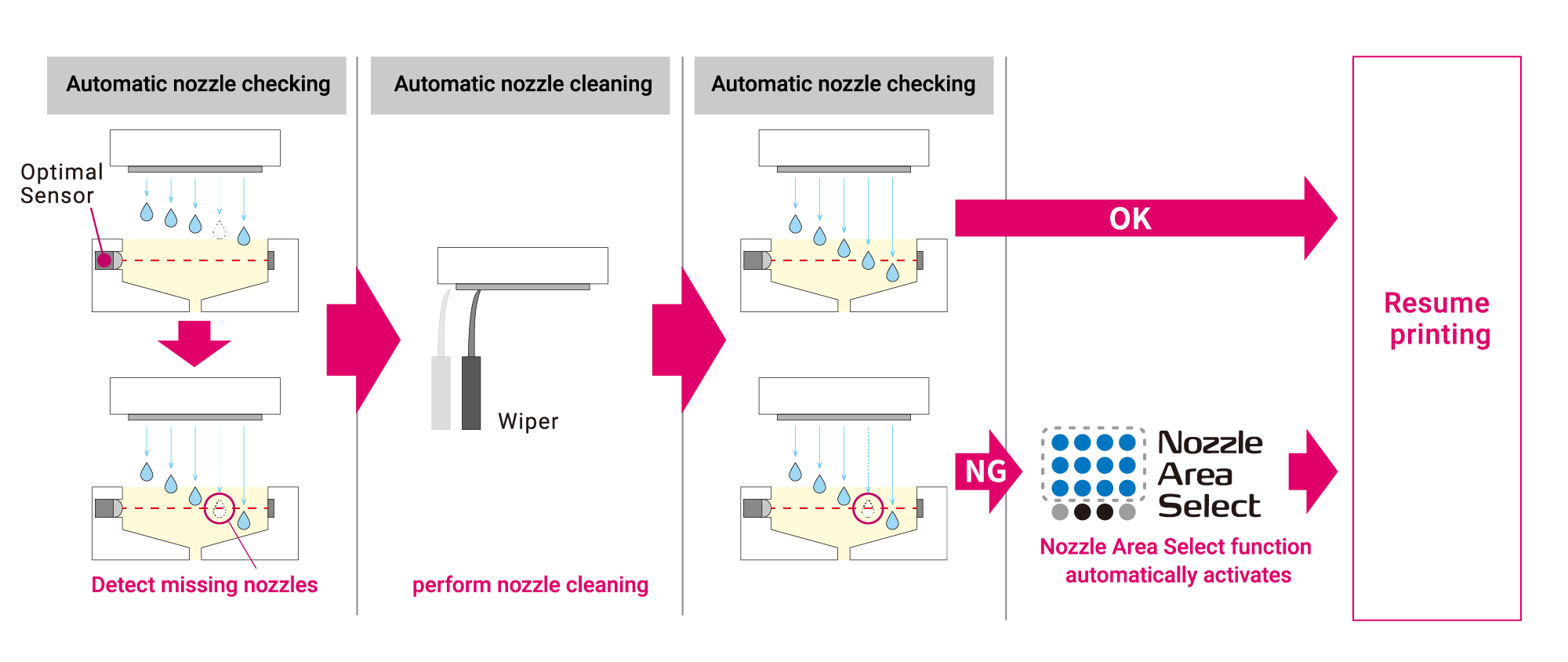

Automatic nozzle checking unit and Nozzle area select

It is available to add a module to the print head that can optically monitor the ink jetting. Automatically detects missing nozzles and performs nozzle cleaning. If nozzles are not recovered, the Nozzle Area Select automatically activates to continue printing.

Signal tower light

The status of the printer can be checked at a glance from a distance.

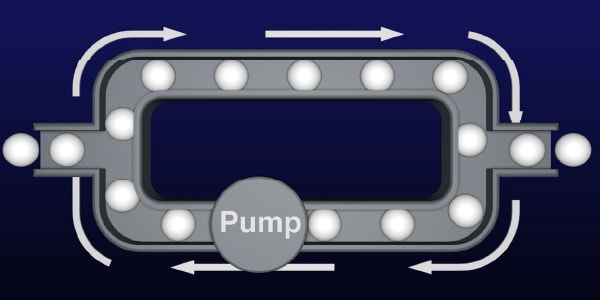

Ink circulation system

Three circulating pumps for white, black and yellow inks are installed to ensure stable color reproduction.

Automatic media detection

The on-board laser sensor automatically detects media thickness up to 150 mm/5.9".

Ionizer (optional)

An optional ionizer eliminates static electricity and supports stable printing.

*The static electricity on the surface of the media is not guaranteed to be eliminated 100%.

MUTOH genuine UV-LED inks

Two types of UV-LED inks are available for beautiful and versatile layered printing.

Next-generation UV ink: US61

US61, a newly developed environmentally friendly UV ink is available for the XpertJet 1462UF. In compliance with the chemical substance regulations in the EU, which has strict environmental regulations, and in anticipation of future regulations, the US61 ink is free of substances classified as CMR Category 1 (1A, 1B)* and SVHC (Substances of Very High Concern). This is a next-generation UV ink that takes into consideration the health of operators and the environment. In addition, it combines “flexibility" and “scratch resistance" at a high level, which have been trade-offs in conventional UV inks, making it suitable for a wide range of applications.

*CMR refers to substances that are carcinogenic, mutagenic, or reproductive toxic. Category 1 is classified as substances that are carcinogenic, mutagenic, or reproductive toxic to humans.

UL

GREENGUARD

Gold

Certification

UV ink specialized for printing on hard materials: UH21

UH21 ink has excellent fastness and scratch resistance. In addition, high adhesion to acrylic (extruded board) allows adhesion without primer application*.

*Ink adhesion test is recommended before printing.

RIP software

Genuine RIP Software

Achieves Unmatched Image Quality and Workflow Efficiency

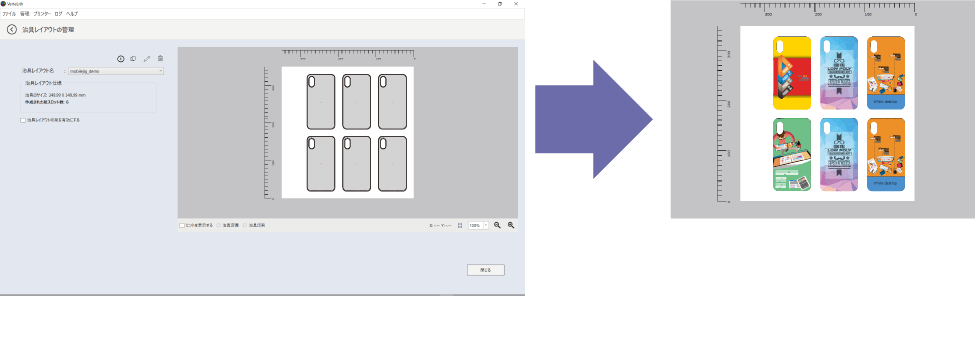

Jig layout function

Less variation in color density and smoother gradations

Simplified jig production with

2.5D printing

Save time and money with MUTOH's automated jig production

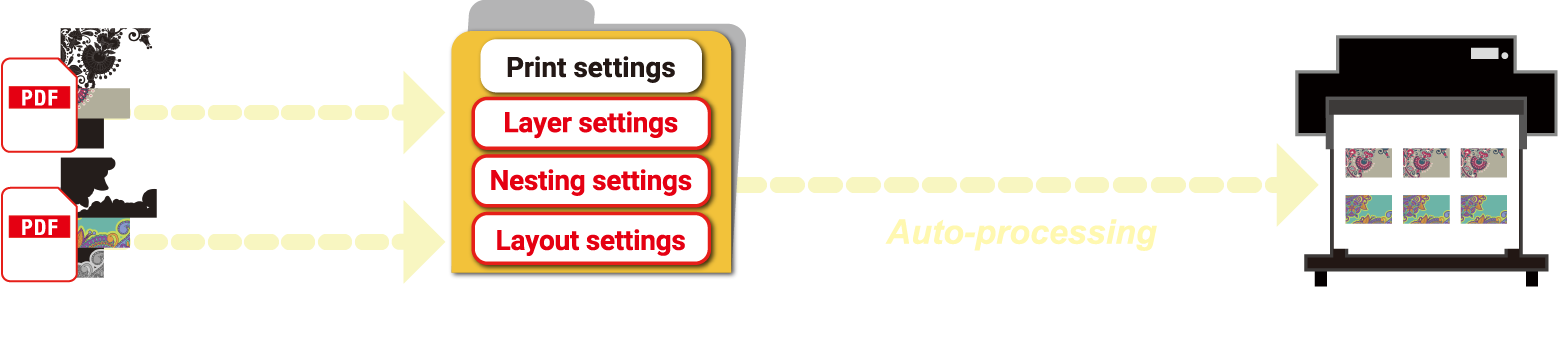

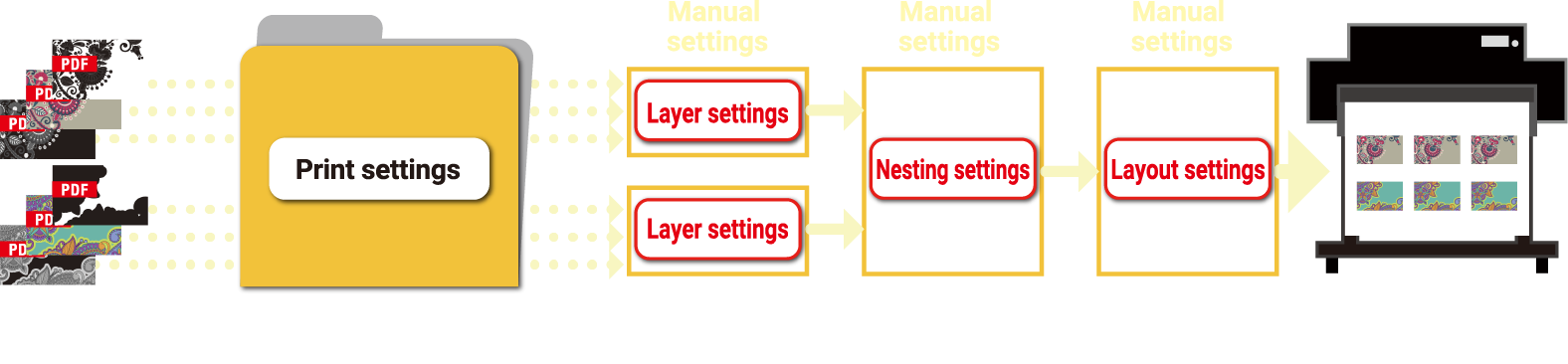

Automated nesting, layout and printing for multiple jobs with multi-layers

For multiple jobs with multi-layers, automated processing can be performed once a series of processing such as print settings, layer settings, nesting settings and layout settings is set in the hot folders.

VerteLith

Conventional process

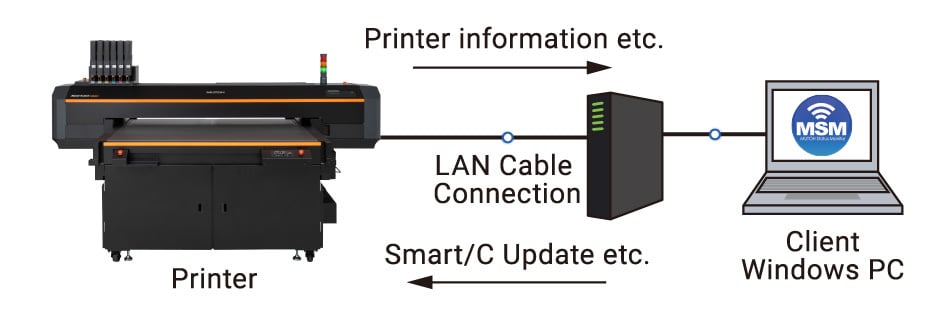

MUTOH Status Monitor(MSM)

MUTOH Status Monitor is software that enables the checking of the printer operation status from a computer in real time.

The following information can be confirmed for your MUTOH printer.

- Detailed information

- Status information

- Heater information

- Print head temperature/cartridge information

- S/C card information

- Smart/C information

- Print information and print history (job information, print time,

ink consumption, cost, etc.)

Print history can be exported as a CSV file.

Promotion movie

XpertJet 1462UF